After decades of development, many new wire drawing die materials have appeared. According to the type of material, wire drawing dies can be divided into alloy steel dies, sintered carbide dies, natural diamond dies, polycrystalline diamond dies, CVD diamond dies. In recent years, the development of new materials has greatly enriched the application range of wire drawing dies and improved the service life of wire drawing dies.

Alloy steel die is an early wire drawing die manufacturing material. The materials used to make alloy steel molds are mainly carbon tool steel and alloy tool steel. However, due to the poor hardness, wear resistance and short life of alloy steel molds, which cannot meet the needs of modern production, alloy steel molds are quickly eliminated, and alloy steel molds are almost invisible in current production and processing.

The Sintered Carbide belongs to tungsten-cobalt alloy, and its main components are tungsten carbide and cobalt. Sintered carbide molds have the following characteristics compared with alloy steel molds: high wear resistance, good polishing, low adhesion, low friction coefficient, low energy consumption, and high corrosion resistance. These characteristics make cemented carbide wire drawing The die has a wide range of processing adaptability and has become the most widely used wire drawing die today.

Natural Diamond is an allotrope of carbon, and the molds made with it have the characteristics of high hardness and good wear resistance. However, natural diamond is brittle and difficult to process. It is generally used to manufacture wire drawing dies with a diameter of less than 1.2 mm. At present, the diameter of the largest diamond die has reached 2.5 mm. In addition, natural diamonds are expensive and in short supply, so natural diamond dies are not the economical and practical wire drawing tools that people are ultimately looking for.

Polycrystalline Diamond is made of carefully selected synthetic diamond single crystals with good quality and a small amount of silicon, titanium and other binders, and is polymerized under high temperature and high pressure conditions. Polycrystalline diamond has high hardness and good wear resistance. Compared with other materials, it has its own unique advantages: due to the anisotropy of natural diamond, during the wire drawing process, when the entire hole is surrounded by In the working state, natural diamond will wear preferentially at a certain position of the hole; while polycrystalline diamond is polycrystalline and has the characteristics of isotropy, thus avoiding the phenomenon of uneven wear of the die hole and out-of-roundness of the die hole. Compared with cemented carbide, the tensile strength of polycrystalline diamond is only 70% of that of commonly used cemented carbide, but 250% harder than cemented carbide, so that polycrystalline diamond molds have more strength than cemented carbide molds. advantage. The wire drawing die made of polycrystalline diamond has good wear resistance, uniform inner hole wear, strong impact resistance, high wire drawing efficiency, and the price is much cheaper than natural diamond. Therefore, polycrystalline diamond dies are widely used in the wire drawing industry.

CVD coating wire drawing die is a new technology developed recently, and its main method is to coat diamond film on the cemented carbide wire drawing die. The diamond film is pure diamond polycrystalline, which not only has the smoothness and temperature resistance of single crystal diamond, but also has the advantages of wear resistance and low price of polycrystalline diamond. Its wide use will bring new vitality to the wire drawing die industry.

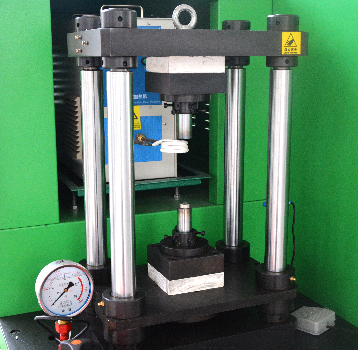

The purpose of Agglomeration is to enhance the diamond's ability to withstand impact without breaking and prolong the life of the die.

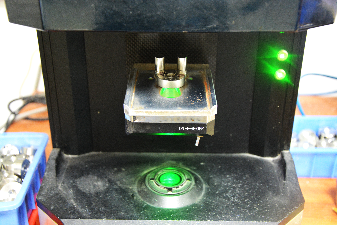

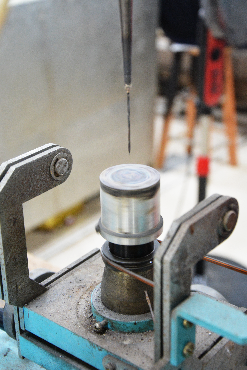

After we set the sleeve out, the die is without holes. We need to send the die to do laser drilling, and the machine will be customized according to the customer's requirement of how big a hole to punch.

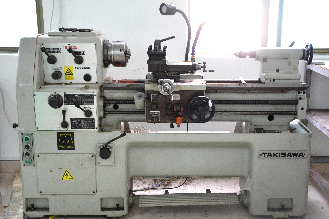

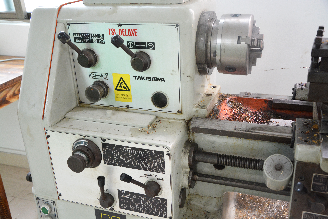

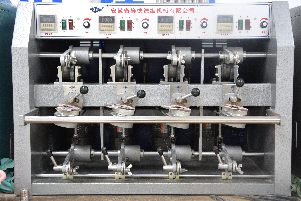

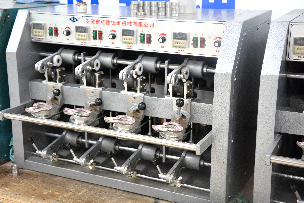

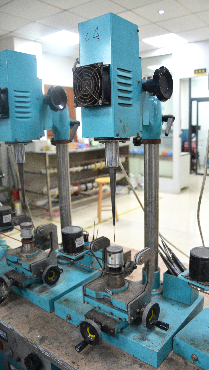

The purpose of the forming machine is to polish the shape of the holes in the die

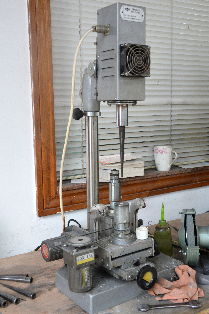

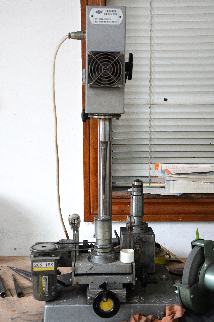

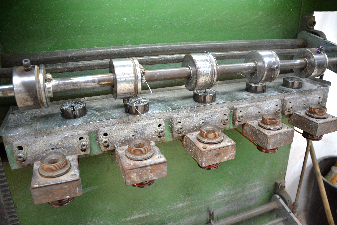

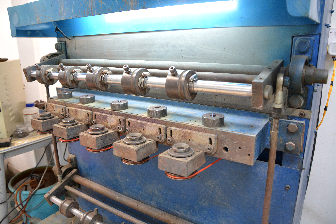

This is the Grinding machine, often used in the polishing of dies

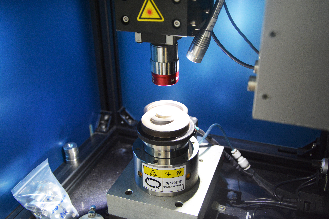

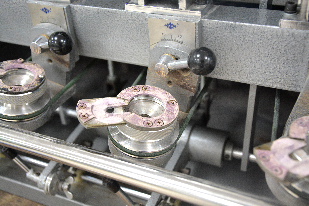

After the die polishing, it needs to be cleaned. After cleaning, you need to come to the last step, which is to test the product with the setting machine.

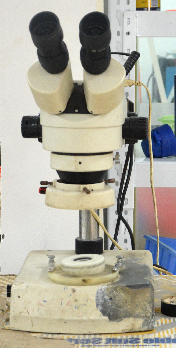

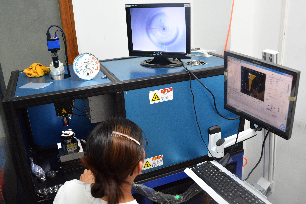

This is a microscope to check whether the hole of the die is qualified or not.