With the development of modern industry and the advancement of scientific skills, new cable mold materials with high strength and high wear resistance are emerging. , and even cannot be processed. Therefore, we chose a new processing method that is different from traditional mechanical processing - special processing. There are many special processing methods, widely used are EDM, WEDM, ultrasonic machining, laser machining, electrolytic machining, etc.

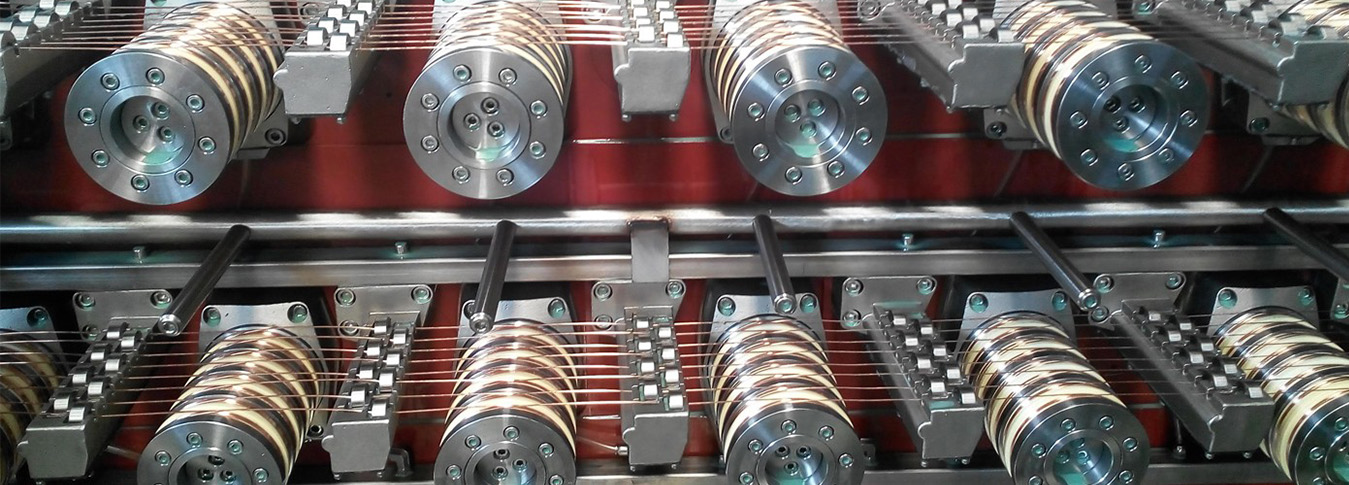

The development of cable dies in the Chinese market is not very long. Even now, many places still need such wire drawing dies, because China's demand for such wire drawing is getting bigger and more refined, so wire drawing dies, in China's future development potential can still be said to be very large.

From the beginning of the research on wire drawing technology in China in the 1980s, it has only been a few decades now. But in just a few decades, the development of China's wire drawing technology is well known to all of us. Therefore, we speculate that with the advancement of wire drawing technology, the demand for very good wire drawing dies in the market will always exist. And this demand trend is about to continue for a long time.

Of course, it can be seen from the current situation in China that the market potential of wire drawing dies is very large. According to the development trend of the market at that time, the further development of cable dies is inevitable, and the development of cable dies is an auxiliary operation, so it must also be demanded. A big improvement can meet the demand for mold skills.

China's reform and opening up in the 1980s led to the development of EDM technology, which has been widely used in the processing of complex and fine molds and parts in the 1990s. In the 21st century, EDM technology has developed rapidly and has become an important part of modern manufacturing technology.

Laser machining and electrolytic machining are both emerging sciences that were developed in the late 1950s and early 1960s after EDM, and their advantages have been increasingly demonstrated in material processing. Special machining is to directly use electrical energy, chemical energy, light energy and sound energy to process the workpiece to achieve a certain shape size and surface roughness requirements. the mechanical force. All of the above methods can be used to process polycrystalline die wire drawing dies.