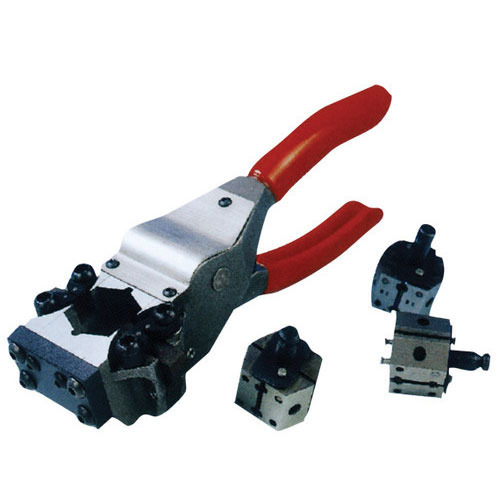

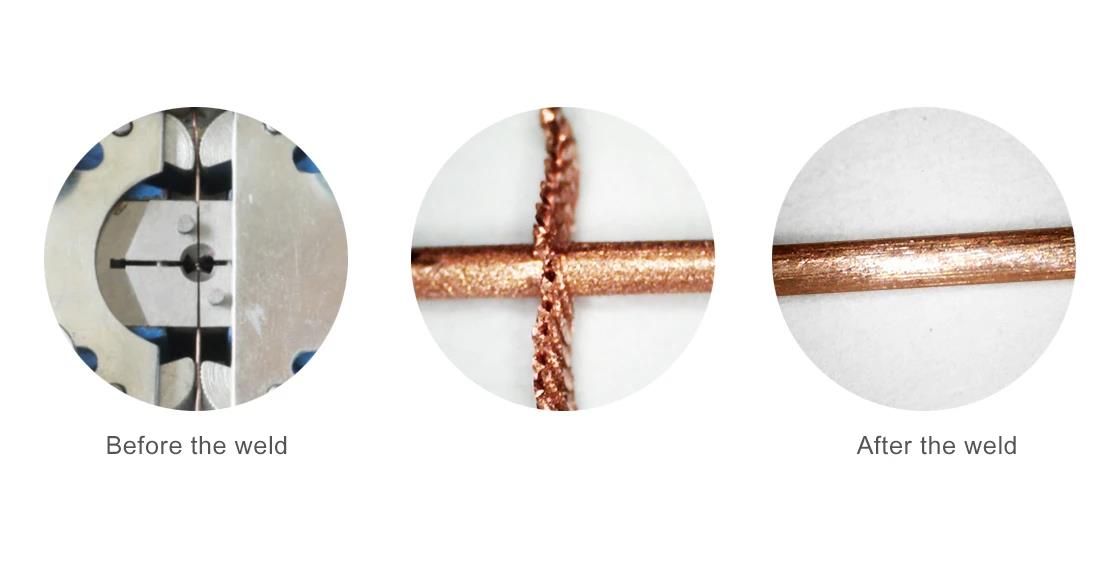

Cold pressure welding is the simplest and most cost-efficient method for connections in electrical coils from copper and aluminum strips with connection bars or leads without using heat, fillers or fluxes. Round wire sections, dissimilar materials and materials of different sizes can all be cold welded with SGT cold welding technology. A cold weld joint is generally stronger than the parent material and has the same electrical characteristics.

And to weld with different conductor . It requires different cable

Ⅰ、Description

| Cold welding is a method for joining non- |

|

Ⅱ、Working process

In order to obtain a true weld, all contaminants (oxides, oils, chemicals etc) must be removed so that clean surfaces can be brought together. BWE cold welding machines achieve this by using a multiple upset technique which ejects the contaminated material from the weld zone eliminating the need for any special preparation.

Ⅲ、Key Features & Benefit

· In the cold weld process.

· Join ferrous and non-ferrous materials.

· welding processes within the wire and cable industry.

· Tight dimension tolerances.

Ⅳ、Applicable machinery