1. Application of SSCD drawing dies:

Synthetic Single crystal diamond (SSCD) is a kind of synthetic diamond with high purity,no impurity and high stability.These quality characteristics also make the material have high hardness and stable wear resistance.

Synthetic single crystal diamond has very similar physical characteristics to natural diamond,so it can be used in all occasions where natural diamond mould can be used.

It is mainly used in fine and ultra-fine wire drawing,or in applications requiring excellent wire surface finish and good heat dissipation performance.

| Product Name SSCD Drawing Dies; MONO Diamond Dies; Single crystal diamond drawing dies | |

| Hole Sizes | 0.050-1.500(mm) |

| Applications |

Used in fine and ultrafine wire sizes, or as finishing dies when wire surface quality is critical. Tungsten wire, plated-copper wire, stainless steel wire and precious metals. |

| Advantages | Single crystal diamond wire drawing die is made of high quality die core,which has the advantages of uniform texture,strong wear resistance,high finish, high precision and long service life. |

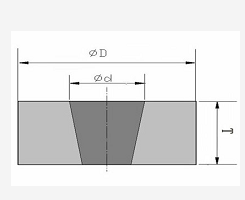

2.Specification Of SSCD Drawing Die

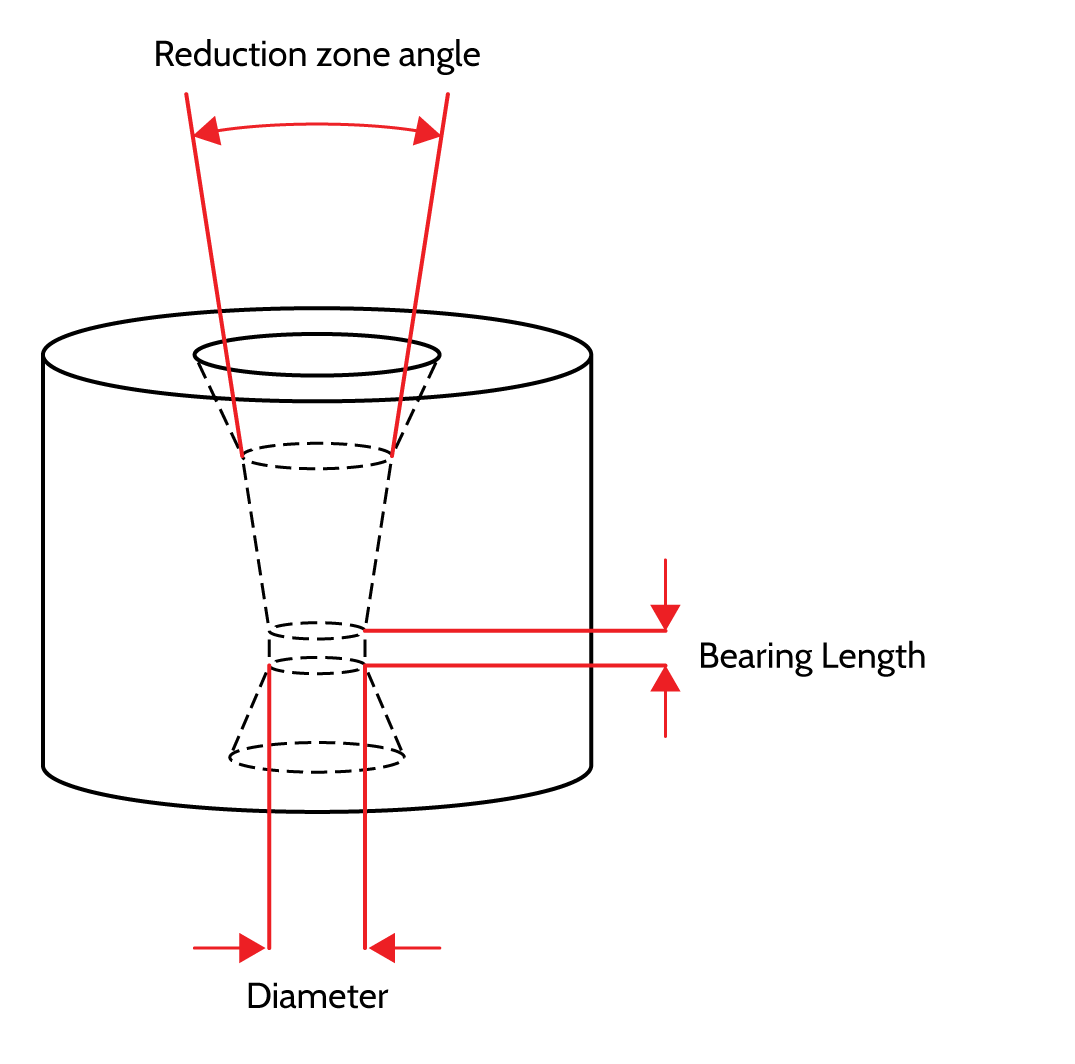

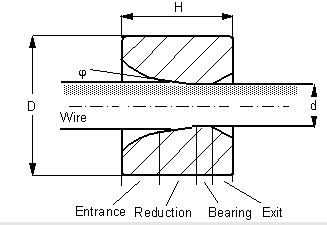

| α(ss)Entrance | The inlet area is polished so that the drawing fluid can circulate smoothly |

| α(sp)Approach | The lubrication area is finely polished, so that the wire can be easily excessive |

| α(rs)Reduction | The working area can reduce the drawing force, and the change-point contact is face-to-face angle drawing, which reduces friction and die wear. The deformed structure is more reasonable and stable. The upper line can be drawn smoothly when the incoming line becomes thicker or thinner. |

| d(k)Bearing | The fixed warp area can ensure the precise diameter, smoothness and out-of-roundness of the wire for a long time. |

| α(so)Back Relief | The safety angle can ensure that the wire is drawn without scratches, and the life expectancy tends to be longer. |

| α(sw)Exit | The deepening of the outlet can greatly support the tensile stress of the outlet. |

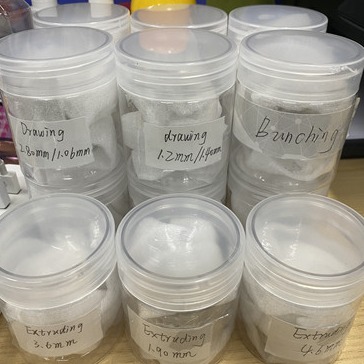

3.PCD DIE PACKING

1.Film Packing

2.Wooden Box Packing

3.Plastic Box Packing

4.Carton Packing

4. Die Maintenance

Sam provides customers with a full set of drawing die maintenance equipment and technical training,as well as diamond drawing dies maintenance services.

The company provides diamond drawing dies repair and polishing maintenance service for customers in wire industry,so that customers can reduce production costs for a long time.

Sam recutting services provide a highly cost-effective way to extend die life and maintain wire drawing quality.

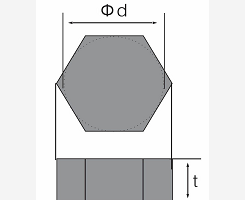

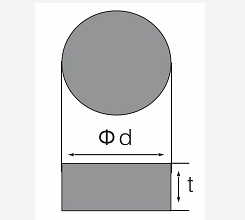

5. SSCD die blank

6.FAQ

1.How about the delivery time?

10-15 days

2.How about the payment?

TT

3.What kind of service u can provide?

Die maintenance

4.How about the packing way?

Film packing, Wooden packing, Carton packing, Plastic box packing

5.Why should buy from u?

10 years experience

Customers from more than 80 countries

Technical department more than 20 engineer