1. Applications of shape die:

Nonfeerous wire, including copper, aluminum, electromagnetic wire and stainless steel.

2. Advantages of shape die:

1. Good durability;

2. High effiency;

3. A wide range of grain and nib sizes;

4.Perfect characteristics of crack proof;

5. Smoothness, durability predicted.

3. Specification of shape die:

| Product Name | Special Shaped Wire Drawing Dies |

| Hole Size | 0.7mm-80mm |

| Tolerance | ±0.001mm-0.05mm |

| Application | Use for drawing Copper wire, aluminum wire, copper-clad steel wire, stainless steel wire,copper-plated wire, tungsten wire,molybdenum wire, chromium wire, nickel wire, etc. |

| Shape | Square,Rectangle,rhombus, flat square,triangle,hexagon,octagon, semicircle,ellipse,sector,Ztype, etc.customizable |

| Types | PCD Drawing Die, Tungsten Steel Wire Drawing Die |

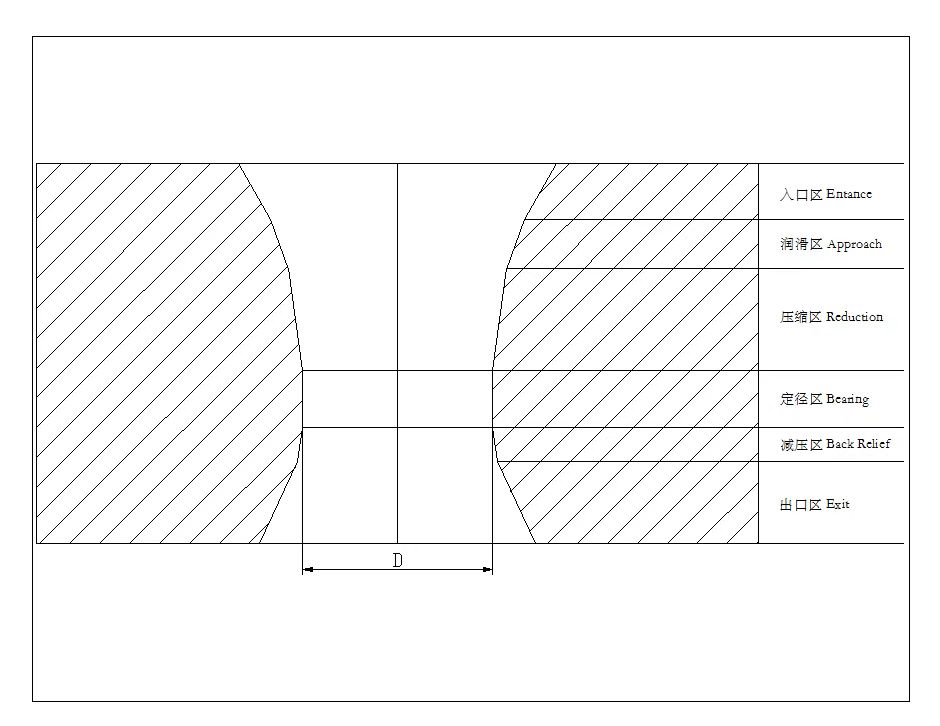

4. Explanation of the working process of the wire drawing die

1. Inlet area: precision polishing is carried out in the inlet area, which is convenient for the smooth threading of the inlet and the rotation of the drawing lubricant;

2. Lubrication area: The lubrication area is highly polished to make the wire transition easily;

3. Compression area: The linear working area can reduce the drawing resistance, change the point contact to the surface contact, reduce friction and die wear, and the deformation structure is more reasonable and stable. It can be drawn smoothly when the incoming wire becomes thicker or thinner in the previous pass;

4. Sizing area: The linear sizing area can ensure the precise diameter, smoothness and out-of-roundness of the wire for a long time.

5. Safety angle: The safety angle can ensure that the wire is pulled out without scars, and the service life tends to be longer and longer.

6.Exit area: The exit area can ensure smooth wire exit.

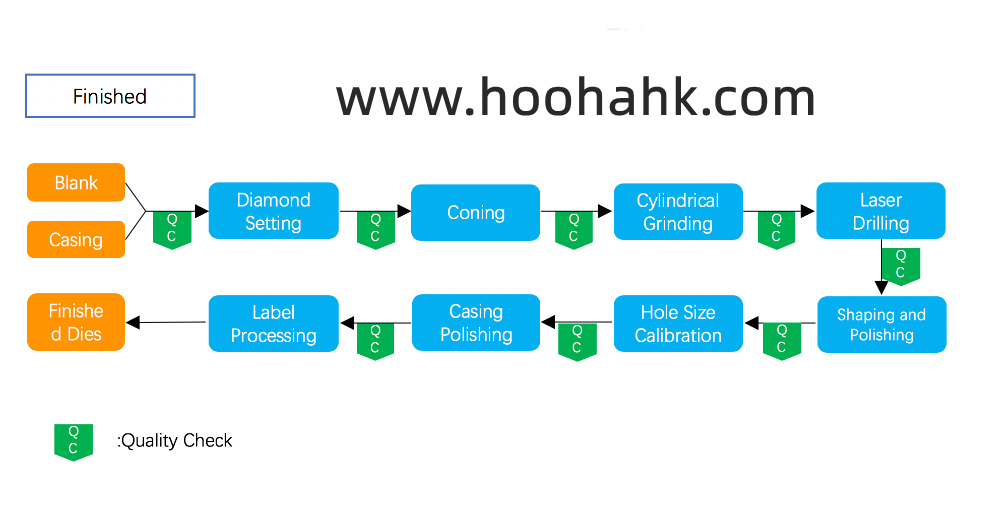

5. Manufacturing of shape die:

1.Raw Material Casting

2. Production( grinding, polishing, cleaning)

3.Finished product(testing)

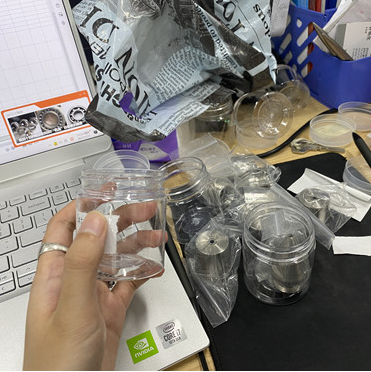

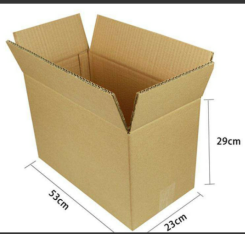

6. Packing of shape dies:

1.Film Packing

2.Wooden Box Packing

3.Plastic Box Packing

4.Carton Packing

7. Die Maintenance of shape die:

Sam provides customers with a full set of drawing die maintenance equipment and technical training,as well as diamond drawing dies maintenance services.

The company provides diamond drawing dies repair and polishing maintenance service for customers in wire industry,so that customers can reduce production costs for a long time.

Sam recutting services provide a highly cost-effective way to extend die life and maintain wire drawing quality.

8.FAQ

1.How about the delivery time?

10-15 days

2.How about the payment?

TT

3.What kind of service u can provide?

Die maintenance

4.How about the packing way?

Film packing, Wooden packing, Carton packing, Plastic box packing

5.Why should buy from u?

10 years experience

Customers from more than 80 countries

Technical department more than 20 engineer